粉體行業(yè)在線展覽

粉體行業(yè)在線展覽

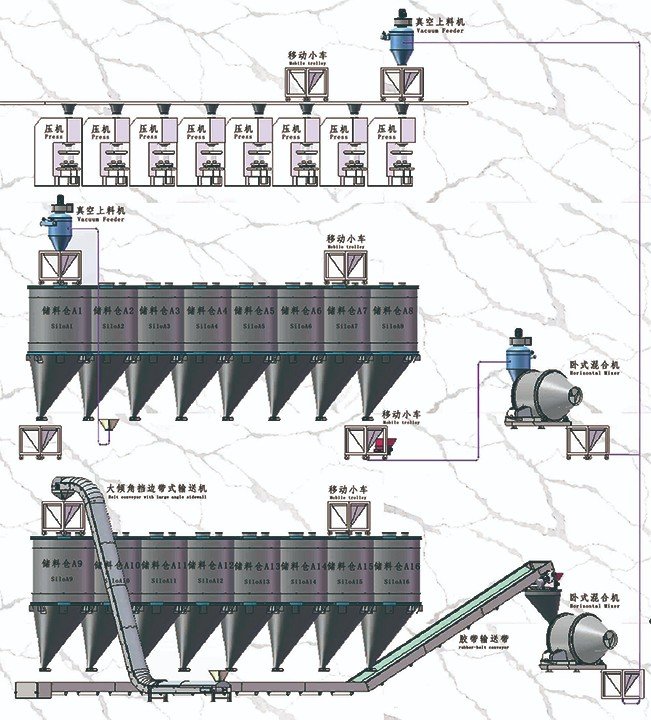

壓機(jī)無塵自動上料均化系統(tǒng)

面議

新聯(lián)和

壓機(jī)無塵自動上料均化系統(tǒng)

2002

無塵車間、壓機(jī)全自動輸送、高效節(jié)能、物料改性、物料均化

壓機(jī)無塵上料系統(tǒng)

系統(tǒng)概述:

1、全流程采用密閉運輸,實現(xiàn)無塵化車間,提高物料的潔凈度。

2、實現(xiàn)多種物料高精度配料,提高車間生產(chǎn)效率和成品率。

3、根據(jù)流程需求系統(tǒng)全自動上料,可實現(xiàn)無人值守,減少人力成本投入。

4、減少設(shè)備投入,系統(tǒng)可實現(xiàn)將物料自動送至多臺壓機(jī)。

5、高效節(jié)能環(huán)保,在大批次送料過程中降低能源消耗。

6、全報表匯總,流程可監(jiān)控,實現(xiàn)車間數(shù)據(jù)可視化。

7、適用于新能源、特種陶瓷、醫(yī)藥、冶金、化工、塑料等行業(yè)的自動定量配料控制。

Automatic loading system for presses

System Overview:

1.The whole process adopts closed transport, realises dust-free workshop, improves the

cleanliness of materials.

2.realises high-precision dosage of many kinds of materials,improves the production,efficiency of workshop and the rate of finished products.

3.according to the demand of the process the system is fully automatic loading,

can realise unattended, reduces the input of manpower cost, reduces the investment

of equipments, the system can realise the material will be automatically sent to more

than one press.

4.the whole report is summed up, the process can be monitored, realises the data ofthe workshop can be visualized.

5.applies to the new energy, the special ceramics, the medicine, the metallurgy, the

chemical, the plastics and so on the industries of the automatic rationing and dosage control.

壓機(jī)無塵自動上料均化系統(tǒng)

球磨機(jī)無塵上料系統(tǒng)

XK-S三維混合機(jī)

XK-Z 臥式混合機(jī)

XK-V V型系列混合機(jī)

XK-S系列雙錐混合機(jī)

XK-H行星式混合機(jī)

XK-A系列混料器

XK-S無重力雙軸漿葉混合機(jī)

XK-W系列臥式螺帶混合機(jī)

XK-J錐型雙螺旋混合機(jī)

XKL梨刀式混合機(jī)